Melt-resistant (Carbonization)

The Advantages of Kanecaron®

- FR & Industries

- What is Protex®?

- Melt-resistant (Carbonization)

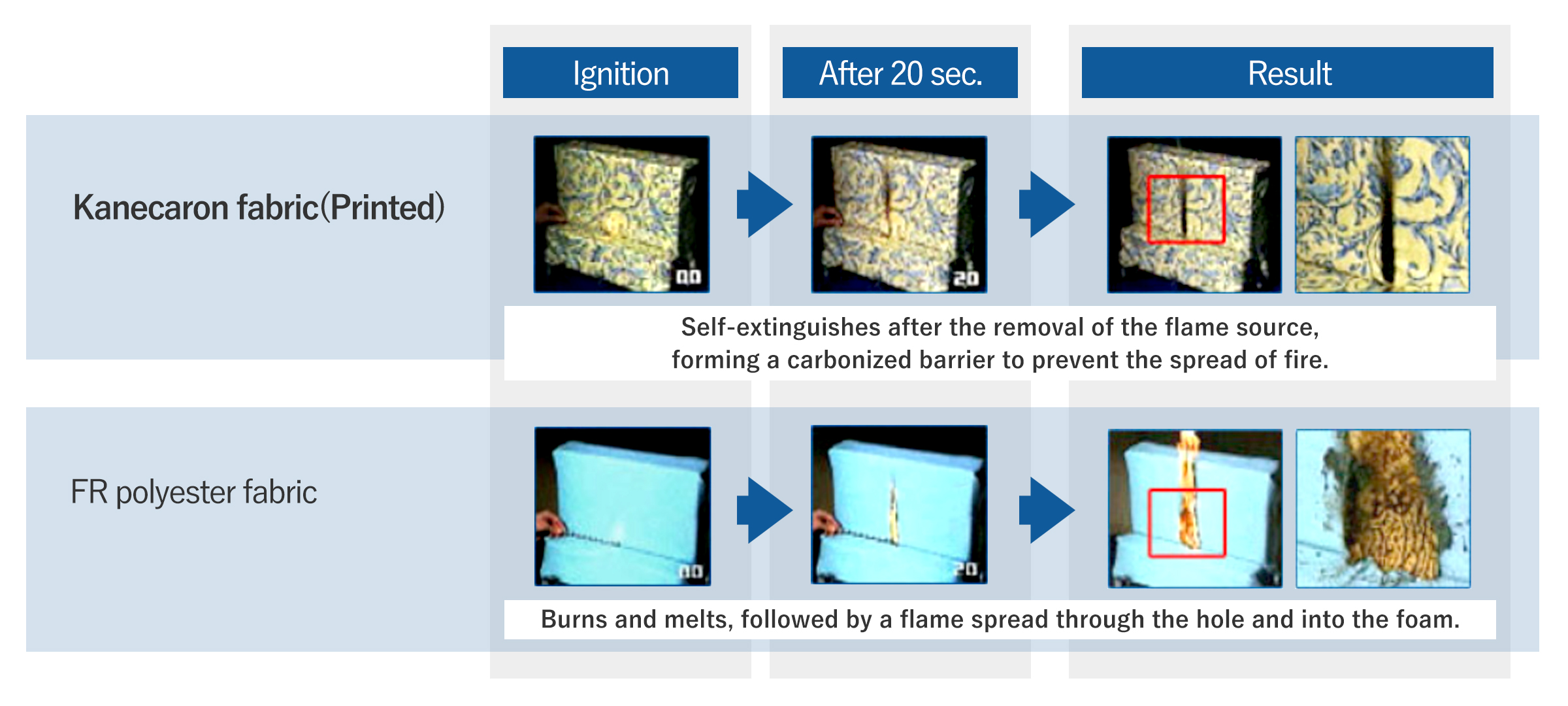

Kanecaron®/Protex® does not melt or drip when ignited. Instead it forms a char barrier through carbonization.

Thermoplastic fibers, such as polyester or nylon, have the potential risk of molten droplets forming which could stick to the skin and cause severe burns. FR polyester shares the same characteristics. Kanecaron®/Protex® helps to reduce the risk of molten droplets when blended with thermoplastic fibers. The degree to which Kanecaron®/Protex® can help reduce the risk of molten droplets will depend on the blend ratio of Kanecaron®/Protex® used.

■The Flame Retardancy of Kanecaron® (BS5852:1990 source) —Upholstery